Cracks will seriously affect the safety and aesthetics of the building. Crack treatment is a problem building restoration, strengthening the field at this stage often encounter. So how will crack strangled in the cradle of its generated it? Now more economical and convenient way to add to the number of fiber in the concrete it!

Increase the use of fiber cementitious materials crack resistance dating back to ancient times, grass reinforcement bars lime brick and paper is the first fiber-reinforced composite materials. Research and Application of synthetic fiber reinforced concrete began in the 1960s, due to the effective control of the non-structural cracks in concrete has been used in many domestic building or expansion projects. Incorporation of polypropylene fibers in concrete in order to improve crack resistance of concrete, reduce plastic shrinkage cracks, improve toughness and impermeability. Polypropylene fiber prices than other synthetic fibers or reinforcing fibers such as cheap steel fiber, carbon fiber, glass fiber, and polypropylene fiber reinforced concrete to facilitate construction operations, it has a broad prospect.

Since the construction of the project requirements in the concrete often have many excess water. The study showed that only 25% of cement mass required around the cement hydration water (ie water-cement ratio of 0.25), while the water-cement ratio in the practical application of the project is much larger than this, it is easy to produce concrete plastic shrinkage cracks. After the polypropylene fibers doped with concrete, the mixing process can be automatically forced evenly distributed in the concrete, which fiber network can be automatically dispersed into two hooked monofilament fiber, both ends of the fiber semi-s-shaped curve, with an increase of concrete bond strength.

Hooked fibers in concrete subjected to tensile stress plastic deformation of concrete, preventing the development of cracks. Meanwhile, a large number of fibers sticking to each other "supporting" the aggregate, reduced water analysis with aggregate concrete surface subsidence, reduces the generation of plastic cracks. Further dehydration, drying of the concrete shrinkage cracks, and the tip of the crack also limited the development of this fiber, these cracks can bypass the fiber or the fiber pull-off to continue the development, which requires enormous energy consumption of polypropylene fiber to overcome the development of cracks. So, it has the effect of polypropylene fiber reinforced concrete of the crack resistance.

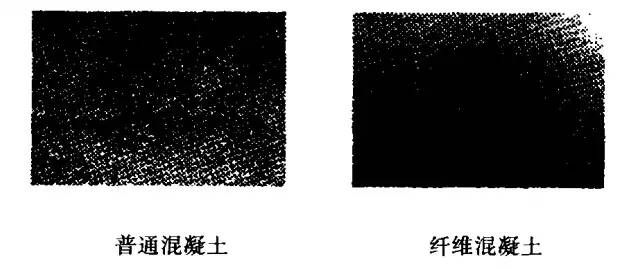

Ordinary concrete and mixed with 0.2% (volume fraction) plastic shrinkage fibers 28h of comparative tests. As can be seen from the figure, not mixed with ordinary polypropylene fiber concrete specimen surface cracks obvious.

Two types of concrete early shrinkage cracks contrast

Jiangsu Sisiyuan Fiber Co., Ltd. Main polypropylene fibers, lignin fibers, cellulose fibers and other fibers used in construction projects. For product details, please call our service hotline!